The Critical Duty of Galvo Scanners in Accuracy Laser Positioning and Control

Galvo scanners, important to the precision and control of laser positioning, use high-speed rotating mirrors to accomplish unmatched accuracy in directing laser beams. What makes these gadgets essential in setups requiring meticulous laser operations?

Recognizing Galvo Scanner Technology

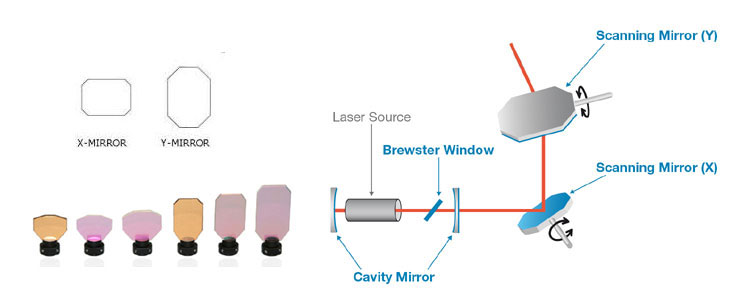

In the world of laser positioning, understanding Galvo scanner innovation is paramount for achieving precision and performance. Galvo scanners, brief for galvanometer scanners, utilize mirrors placed on galvanometers to direct laser beams with high accuracy and rate. These mirrors can quick, precise angular movements, enabling the laser beam of light to be guided to precise works with on a target surface area.

The operational principle of a Galvo scanner revolves around the galvanometer device. A galvanometer transforms electric current into mechanical motion, causing the mirror to pivot. By managing the electric present, the mirror's angle is precisely adjusted, enabling specific laser positioning (galvo scanner). This is critical in applications such as laser engraving, medical imaging, and optical communication, where precision is necessary.

High-resolution encoders are usually incorporated right into Galvo scanners to give real-time responses on the mirror's placement, making certain marginal variance from the desired course. This responses loophole improves the scanner's accuracy and repeatability, making it an important tool in industries requiring precise laser guidance. Understanding the details of Galvo scanner modern technology is therefore vital for leveraging its full potential in advanced laser applications.

Devices of Laser Positioning

Efficient laser positioning relies upon numerous advanced mechanisms to achieve high precision and accuracy. At the heart of these mechanisms are galvanometer (galvo) scanners, which make use of turning mirrors to direct the laser beam with impressive speed and control. The core concept entails transforming electrical signals right into accurate angular movements with the galvo motor, which after that changes the mirror's alignment to guide the laser beam to the preferred location.

One more important element is the control system, which incorporates comments loopholes to continuously remedy the laser and monitor's setting. This ensures very little deviation from the target collaborates, boosting the general accuracy. The usage of innovative servo controllers enables real-time changes, making up for any type of disparities that may arise during procedure.

These systems jointly allow reliable and exact laser positioning, essential for applications requiring strict precision.

Benefits of Utilizing Galvo Scanners

Galvo scanners offer various benefits that make them indispensable in precision laser applications. The high-resolution comments go to website systems incorporated right into galvo scanners guarantee minute modifications, therefore boosting precision and repeatability in laser positioning.

Furthermore, galvo scanners display remarkable adaptability. They can be programmed to carry out complicated scanning patterns and suit various beam sizes and shapes. This adaptability is vital for jobs that require detailed laser courses, such as engraving detailed designs or performing great procedures.

Reliability is another vital benefit. Galvo scanners have a robust design with minimal moving parts, minimizing the likelihood of mechanical failing. This leads to much longer functional life expectancies and reduced upkeep costs, ensuring regular performance over prolonged durations.

Additionally, the small form element of galvo scanners permits for simple assimilation into diverse systems. Their little dimension does not endanger their efficiency, making them suitable for applications with spatial restrictions.

Applications in Numerous Industries

Laser positioning systems utilizing galvo scanners have actually reinvented numerous sectors by boosting effectiveness and precision. In the manufacturing market, these systems are indispensable to laser cutting and inscribing processes, providing unmatched accuracy and speed. Automotive and aerospace industries gain from the exact welding and boring abilities of these systems, making certain elements satisfy rigorous top quality criteria.

In the clinical area, galvo scanners are important in laser surgical treatment and eye therapies, where precision is crucial for person safety and security and successful end results. Dermatology and aesthetic procedures additionally depend on these systems for jobs like tattoo elimination and skin resurfacing. Furthermore, the electronics sector utilizes galvo scanners for PCB (Printed Circuit Board) fabrication, allowing the production of detailed circuit patterns with high repeatability.

Additionally, in the area of scientific research study, galvo scanners are essential in innovative microscopy techniques, such as confocal and two-photon microscopy, permitting researchers to record high-resolution pictures of biological samplings. The art and show business also use these systems in laser light shows and holography, developing vibrant visual experiences. Overall, the versatility and precision of galvo scanners drive technology and operational excellence throughout a wide range of fields.

Future Technologies and Trends

As technical improvements proceed to increase, the future of galvo scanners in laser placing systems assures groundbreaking technologies and emerging trends. One substantial trend is the combination of expert system (AI) and machine discovering (ML) algorithms to boost the precision and adaptability of galvo scanners. These smart systems can anticipate and remedy variances in real-time, bring about greater accuracy and efficiency in laser applications.

One more arising fad involves the development of ultra-fast galvo scanners with the ability of managing higher laser power and rate without compromising on precision. This advancement is specifically vital for industries such as semiconductor production and medical device construction, where even minute errors can cause substantial losses.

Additionally, the miniaturization click this link of galvo scanner parts is anticipated to open new applications in mobile and wearable gadgets (galvo scanner). Advancements in micro-electromechanical systems (MEMS) innovation are leading the means for more compact, yet highly efficient, galvo scanners

Lastly, content raised emphasis on sustainability and power efficiency will certainly drive the growth of environmentally friendly galvo scanner systems. By integrating energy-efficient elements and maximizing operational procedures, future galvo scanners will not just boost performance however also add to a much more sustainable technological community.

Conclusion

Galvo scanners are essential in precision laser positioning and control due to their capability to transform electric signals into accurate angular movements. These features make galvo scanners important in industries calling for thorough laser operations, such as laser inscription and medical procedures.

Galvo scanners, indispensable to the accuracy and control of laser positioning, utilize high-speed rotating mirrors to attain unrivaled precision in guiding laser beams. Galvo scanners, brief for galvanometer scanners, utilize mirrors placed on galvanometers to guide laser light beams with high precision and speed. The high-resolution responses systems integrated right into galvo scanners make sure minute adjustments, therefore enhancing precision and repeatability in laser positioning.

Comments on “Galvo Scanner Systems for Precision Laser Beam Of Light Guiding”